If a job in work in process has recorded actual labor costs of 6,000 for the accounting period then the predetermined overhead applied to the job is calculated as follows. In order to estimate the predetermined overhead rate it is first necessary to to decide on an activity base on which to apply overhead costs to a product. The company, having calculated its overhead costs as $20 per labor hour, now has a baseline cost-per-hour figure that it can use to appropriately charge its customers for labor and earn a profit. That is, the company is now aware that a 5-hour job, for instance, will have an estimated overhead cost of $100. The predetermined overhead rate formula can be used to balance expenses with production costs and sales. For businesses in manufacturing, establishing and monitoring an overhead rate can help keep expenses proportional to production volumes and sales.

How to calculate a predetermined overhead rate

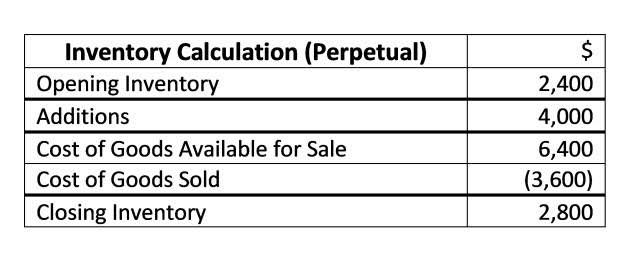

- If the actual overhead at the end of the accounting period is 1,575 the overhead is said to be under applied by 75 (1,500 – 1,575) as shown in the table below.

- If the predetermined overhead rate calculated is nowhere close to being accurate, the decisions based on this rate will definitely be inaccurate, too.

- This is because using this rate allows them to avoid compiling actual overhead costs as part of their closing process.

- He has been a manager and an auditor with Deloitte, a big 4 accountancy firm, and holds a degree from Loughborough University.

- One of the advantages of predetermined overhead rate is that it can help businesses monitor overhead rate.

For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March. For these reasons, most companies use predetermined overhead rates rather than actual overhead rates in their cost accounting systems. These overhead costs involve the manufacturing of a product such as facility utilities, facility maintenance, equipment, supplies, and labor costs.

AccountingTools

- Again the actual overhead at the end of the accounting period is 1,575 and the overhead is said to be under applied by 81 (1,494 – 1,575) as shown below.

- However, the difference between the actual and estimated amounts of overhead must be reconciled at least at the end of each fiscal year.

- Therefore, the JKL’s predetermined manufacturing overhead rate for the new year will be $60 ($1,200,000/20,000) per production machine hour.

- For this example, we’ll say the marketing agency estimates that it will work 2,500 hours in the upcoming year.

- Fixed costs are those that remain the same even when production or sales volume changes.

Conversely, the cost of the t-shirts themselves would not be considered overhead because it’s directly linked to your product (and obviously changes based on the volume of products you create and sell). The overhead will be allocated to the product units at the rate of 10.00 for each machine hour used. Two companies, ABC company, and XYZ company are competing to get a massive order that will make them much recognized in the market. This project is going to be lucrative for both companies but after going over the terms and conditions of the bidding, it is stated that the bid would be based on the overhead rate. This means that since the project would involve more overheads, the company with the lower overhead rate shall be awarded the auction winner. Fixed costs are those that remain the same even when production or sales volume changes.

How to calculate the predetermined overhead rate: Example 3

Further, it is stated that the reason for the same is that overhead is based on estimations and not the actuals. Suppose that X limited produces a product X and uses labor hours to assign the manufacturing overhead cost. The estimated manufacturing overhead was $155,000, and the adjusting entries estimated labor hours involved were 1,200 hours. It’s calculated by obtaining budgeted cost and level of activity, and it’s preferred over actual overheads because estimates can include seasonal variations and other estimates. As you can see, calculating your predetermined overhead rate is a crucial first step in pricing your products correctly. If the predetermined overhead rate calculated is nowhere close to being accurate, the decisions based on this rate will definitely be inaccurate, too.

Sales and production decisions based on this rate could be faulty

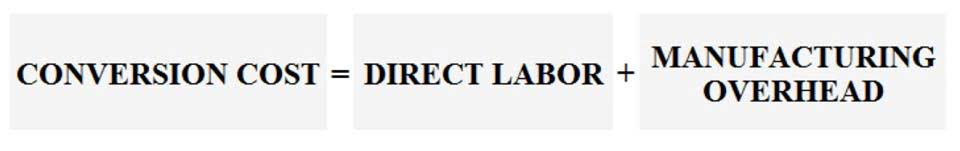

- But before we dive deeper into calculating predetermined overhead, we need to understand the concept of overhead itself.

- Nonetheless, it is still essential for businesses to reconcile the difference between the actual overhead and the estimated overhead at the end of their fiscal year.

- A large organization uses multiple predetermined overhead recovery rates to allocate its expenses to the cost centers.

- However, small organizations with small budgets cannot afford to have multiple predetermined overhead allocation mechanisms since it requires experts to determine the same.

- These overhead costs involve the manufacturing of a product such as facility utilities, facility maintenance, equipment, supplies, and labor costs.

- You should calculate your predetermined overhead rate at least once per year.

- It’s because actual overheads vary from period to period based on seasonal variation and changes in the external environment.

To calculate their rate, the marketing agency will need to add up all of its estimated overhead costs for the upcoming year. Predetermined overhead rates are important because they provide a way to allocate overhead costs to products or services. In larger companies, each department in which different production processes take place usually computes its own predetermined overhead rate. Take, for instance, a manufacturing company that produces gadgets; the production process https://www.bookstime.com/articles/quickbooks-self-employed of the gadgets would require raw material inputs and direct labor.

- At a later stage, when the actual expenses are known, the difference between that allocated overhead and the actual expense is adjusted.

- For example, let’s say the marketing agency quotes a client $1,000 for a project that will take 10 hours of work.

- It’s essential to fully understand the allocation base and allocation rate or variance for the predetermined overhead rate.

- As the production head wants to calculate the predetermined overhead rate, all the direct costs will be ignored, whether direct cost (labor or material).

- Hence, this predetermined overhead rate of 66.47 shall be applied to the pricing of the new product VXM.

- For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March.

For example, the costs of heating and cooling a factory in Illinois will be highest in the winter and summer months and lowest in the spring and fall. If the overhead rate is recomputed at the end of each month or each quarter based on actual costs and activity, the overhead rate would go up in the winter and summer and down in the spring and fall. As a result, two identical jobs, one completed in the winter and one completed in the spring, would be assigned different manufacturing overhead costs. To avoid such fluctuations, actual overhead predetermined overhead rate rates could be computed on an annual or less-frequent basis. However, if the overhead rate is computed annually based on the actual costs and activity for the year, the manufacturing overhead assigned to any particular job would not be known until the end of the year.

Leave A Comment